Mainly used for High Temperature Co-fired Ceramic (HTCC) in high temperature nitrogen and hydrogen atmosphere co-firing process, and also can be used for other related products in high temperature atmosphere sintering process.

2. Mainly Specifics:

- Rated Temp: 1600ºC

- Max Temp: 1700ºC

- Effective Dimensions: 400 × 400 × 500mm(W×H×D)

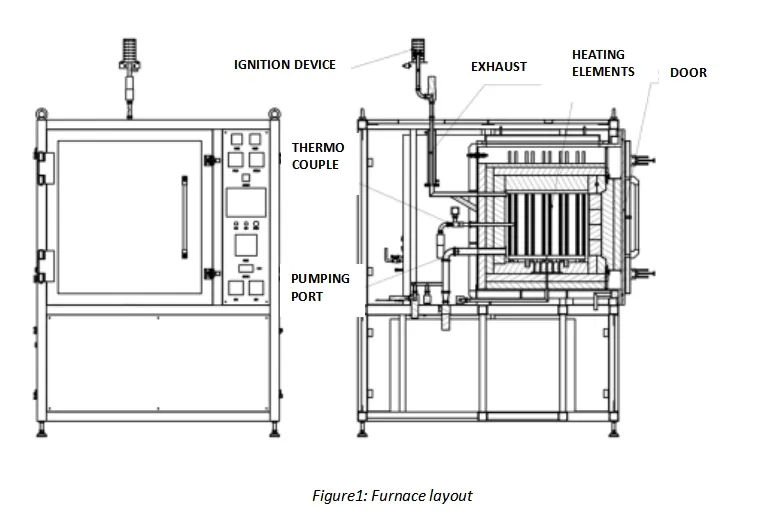

- Heating Method: U-shaped molybdenum coil

- Process Atmosphere: nitrogen/hydrogen (optional humidification function)

- Temperature Control Stability: ±1ºC, with PID parameter self-tuning function

- Temperature Uniformity: better than ±5ºC (1600ºC insulation 2 small time and space furnace test)

- Thermocouple: B Type

- Temperature control points: 1

- Temperature measurement points: 1 point

- Number of Temp. Profiles: 19×19 (the temperature controller can save 19 profiles, each profile can be set 19 steps)

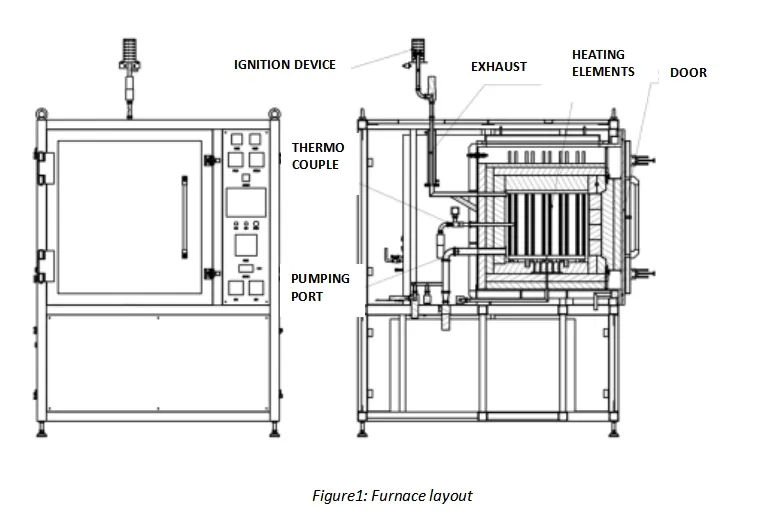

- Exhaust: One exhaust port with ignition device

- Alarm System: over temperature, thermocouple failure and other abnormal conditions will activate sound and light alarm protection, over temperature heating power will turn off automatically

- Max Heating Power: 25kW

- Insulation Power: ≤15kW

- Heating Rate: RT - 1000ºC ≤ 5ºC/min, 1000 - 1600ºC ≤ 2ºC/min

- Surface Temperature Rise: < 35ºC

- Weight: about 1600kg

- Furnace Dimensions: about 1570×2050×1830mm (W×H×D);

- Appearance Color: light gray

| 3. Delivery List |

|

Item |

Note |

QTY |

| Basic Compositions |

Furnace |

|

1 PC |

| Certificates of Inspection |

Furnace and major purchased components |

1 Set |

| Technical Documents |

Furnace specifications, technical documents of major purchased components, etc |

1 Set |

| Key Parts |

Heating Elements |

Molybdenum Coil |

1 Set |

| Thermocouple |

Watlow, THERMOWAY, B Type |

1 PC |

| Temperature Controller |

CHINO |

1 Set |

| Monitor |

Proface 10" touch screen |

1 Set |

| Vacuum Pump |

VALUE, 100m³/h |

1 Set |

| Oxygen Analyzer |

CHANG'AI |

1 Set |

| Mass Flowmeter |

HORIBA |

2 Sets |

| Flow Indicator |

HORIBA |

2 Sets |

| Dew Point Probe |

VAISALA |

1 Set |

| Spares |

Heating Elements |

Molybdenum Coil |

1 PC |

| 4. Optional Items |

| Item |

Note |

QTY |

| Humidifier |

humidifying chambers: 2 (nitrogen, hydrogen)

Power: 2.5kW

Control Mode: PID Control |

1 Set |

| Hydrogen Alarm System |

Detection Range: 0 - 5000ppm

Resolution: 1ppm |

1 Set |

Gas Treatment Equipment

(Connect to Furnace Exhaust) |

Burning Temp.: 750 - 850ºC

Max Power: 12kW

Burning Method: Electric heating

Control Mode: PID Control

Max Process Capacity: 50Nm3/h |

1 Set |

| Chiller |

Standard cooling capacity: 2451Kcal/h

Power Supply: 220V, 50Hz(TBD)

Power: 1.22kW

Pipe Type: 1/2"

Lift: 20m |

1 Set |

5. Facility Requirements

5.1 Environmental conditions: Temperature 0 - 40ºC, humidity ≤ 80% RH, no corrosive gas, no strong

airflow disturbance.

5.2 Process air conditions: nitrogen, purity 99.999%, air source pressure 0.2 - 0.4Mpa, gas

consumption 3 - 6m3 /h; Hydrogen, purity 99.99%, gas source pressure not less than 0.1Mpa, gas consumption is 0.6 - 6m3 /h;

5.3 Power air source conditions: clean, dry, oil-free compressed air, pressure 0.4 - 0.8Mpa;

5.4 Water Inlet condition: 0.1 - 0.3Mpa, clean, no corrosion, supply flow 2 - 5L/min;

5.5 Ventilation system: non-contact access to the user pumping system, pumping capacity is greater

than 10m3 /h;

5.6 Ground requirements: level, no obvious vibration, bearing capacity > 500Kg/m2 .

5.7 Power conditions: capacity greater than 35kVA, 3 phases 5 lines, voltage 220/380V, frequency

50Hz(according to local situation). Live wire: yellow, green, red, neutral wire: blue, ground wire: yellow-green;

5.8 Installation site: 2500mm×3000mm×2500mm (W×H×D), installation area greater than 7m2.

Hefei Chitherm Equipment Co., Ltd. is an advanced equipment supplier specializing in the research and development, design, manufacturing, sales, maintenance, and service of high-, medium-, and low-temperature industrial furnaces and laboratory furnaces. Its product range encompasses bell furnaces, box furnaces, hot air furnaces, vacuum furnaces, tube furnaces, mesh belt furnaces, bogie hearth furnaces, rotary furnaces, roller hearth furnaces, and pusher furnaces, which are extensively applied in fields such as advanced ceramics, electronic components, thick-film circuits, additive manufacturing, powder metallurgy, new energy, and photovoltaics. These furnaces are suitable for thermal treatment processes of materials including ITO targets, MLCC/HTCC/LTCC, ceramic filters, magnetic materials, CIM/MIM, and lithium battery cathodes and anodes, as well as various other new material processes such as pre-sintering, dewaxing, degreasing, sintering, drying, heat treatment, curing, and ceramization.

1.What products does Chitherm offer?

We provide customers with high-quality bell furnaces, hot air furnaces, box furnaces, tube furnaces, vacuum furnaces, car bottom furnaces, rotary kilns, mesh belt furnaces, and pusher furnaces.

2.What pre-sales services does Chitherm provide?

We offer timely consultation services to help customers select the most suitable products, along with highly customizable solutions to meet your specific requirements.

3.What are Chitherm's core strengths?

As a high-tech enterprise integrating R&D, manufacturing, and sales, Chitherm possesses patented technologies and core resources to deliver superior solutions.

Your message must be between 20-3,000 characters!

Please check your E-mail!

Your message must be between 20-3,000 characters!

Please check your E-mail!